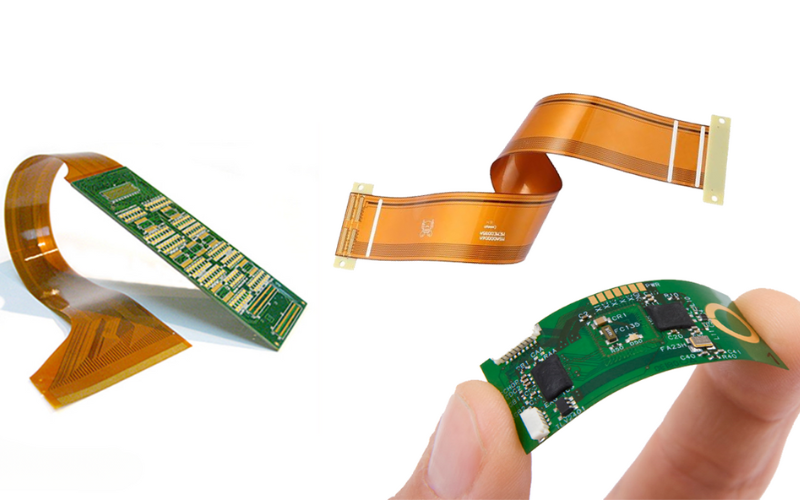

Flexible PCB, or Flexible Printed Circuit Boards, refer to a type of circuit board that can be bent or flexed to accommodate tight spaces or unique shapes. These PCBs are typically constructed using flexible plastic substrates and utilize flexible copper conductors to transmit electrical signals.

Designed for both static and dynamic applications, flexible PCB offer versatility in various scenarios. Static flexible PCB are suitable for applications where the board remains in a fixed position without bending during regular use. On the other hand, Dynamic Flex PCBs are specifically engineered to endure repeated bending or flexing in normal operation. The flexible design of these PCBs allows them to be employed in situations where space is limited or where the circuit board needs to conform to non-planar surfaces.

For your specific needs, consider exploring wholesale flex PCB and custom flex PCB options to fulfill your requirements in a cost-effective and tailored manner.

If you need a manufacturer that can make a flexible PCB for you, you should make sure that the PCB manufacturer has a mature, current process for manufacturing flexible circuit boards. Considering factors such as manufacturing costs, we recommend that you choose a Chinese PCB manufacturer. Because, at present, PCB manufacturing industry is basically concentrated in China. Not only because China's manufacturing industry is very developed, but also because it has a very mature production process that can effectively reduce the cost of manufacturing products for you. To tour our factory,

Various types of flexible PCBs can be manufactured to cater to different needs, including Single-Sided Flex PCBs, Double-Sided Flex PCBs, Single-Layer Flex PCBs, Multi-Layer Flex PCBs, and Rigid-Flex PCBs. Below are the details of each flexible PCB type along with their characteristics and applications.

Single-Sided Flex PCB

Single-Sided Flex PCB consists of a single layer of flexible substrate material with copper conductors on one side. These are the simplest and most cost-effective types of flexible PCBs to manufacture.

These flexible PCBs are often used in applications where flexibility is a primary concern or where space is extremely limited, as they can be very thin and suitable for tight spaces.

One drawback of Single-Sided Flex PCB is limited wiring options, as all conductors must be placed on a single layer. This can make the design of complex circuits or circuits requiring a significant amount of interconnection challenging.

Double-Sided Flex PCB

This is a flexible circuit board with conductive material on both sides of the flexible substrate, typically made of polyimide, though other materials like

polyester

fiber can also be used.

Double-Sided Flex PCBs can be designed to include through-holes connecting conductive materials on both sides, allowing for more complex circuits.

These PCBs are commonly used in applications where flexibility or the advantage of reduced weight and volume is beneficial without compromising the demand for complex wiring or circuits.

Multi-Layer Flex PCB

As the name suggests, Multi-Layer Flex PCB consists of multiple layers of conductive material embedded within the flexible substrate. These layers are then interconnected through through-holes, small holes drilled through the substrate to provide electrical connections.

Multi-Layer Flex PCBs are typically more complex and have higher manufacturing costs compared to Single-Sided or Double-Sided Flex PCBs.

They require more design considerations and a stricter manufacturing process. However, the structure of these flexible PCBs offers numerous advantages, such as higher interconnect density.

Rigid-Flex PCB

Rigid-Flex PCBs are composed of both flexible and rigid substrate materials, connected to create a unified unit. Ideally,

they combine the flexibility of flexible PCBs with the rigidity of standard non-flexible PCBs.

These types of flexible PCBs can bend or fold to conform to the shape of the devices they are used in while still providing the necessary rigidity for mounting components or connecting to other circuit boards.

For your specific requirements, consider exploring options from China flex PCB, flex PCB China, and China flex PCB factory to ensure cost-effective and high-quality solutions.